How To Design A Dust Collection System

If you found this page, you may be looking for an answer to the question: “How does a dust collector work?” After all, that is a popular search. So, if you have been looking for how to design a dust collection system, you might find some good things to keep in mind in this article. We will look at some important factors to consider if you are looking to find out about dust collection systems.

How Does A Dust Collection System Work?

Dust collection systems come in a variety of types. Additionally, each type of dust collector has a different purpose. So the first step we need to take is to define the kind of dust collector we will be describing. Here, we will be talking about a free standing machine that sits adjacent to the workspace and filters out dust particles.

As the short description just mentioned indicates, there are machines that are stationed next to a work area that filter the dust from the air in the environment. So how does one of these dust collection systems work? And better yet, how would you design one?

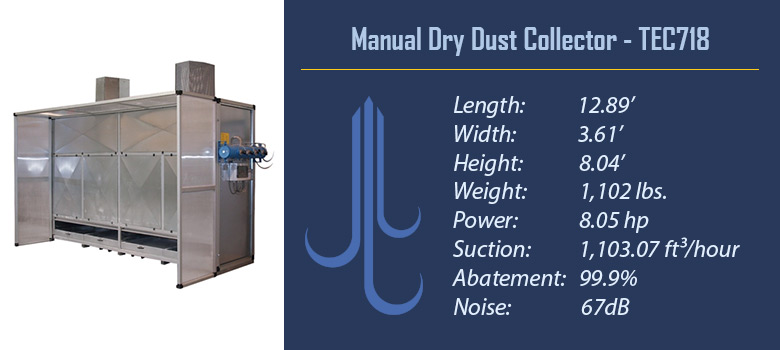

The kind of dust collector we will talk about in this post is one similar to this dry dust booth. On that page you will find the description of how these dust collectors work, however, here is a quote form that page:

When the motor is running, the collector draws in stone dust. Specially designed cloth filtering sleeves filter air as it passes through the unit and circulates back into the shop. However, dust particles are captured and not allowed through the filters. The filtering sleeves retain the stone dust in the catch basin at the bottom of the dry collection system.

What to Consider When Designing A Dust Collector

As mentioned before, when one designs a dust collection system, there are a number of factors to keep in mind; each having a role in the finished product. Here, we will look at three, they are:

- Effectiveness

- Efficiency

- Ease of Use

Why Effectiveness Matters

The first thing to keep in mind when you set out to design a dust collection system is how well it needs to perform. This matters because there are specific standards set out by OSHA that you will no doubt want to meet. For example, the permissible exposure limit (PEL) is 50 micrograms per cubic meter. So, your dust collector design should meet this standard.

This means that you will want to consider ways to maximize the dust removal capability of the system you are designing. However, making your dust collector effective is only one aspect of the design; there is more to think about.

Making A Dust Collector Efficient

There are some basic things to keep in mind when making your dust collector more efficient. After all, efficiency means that the system gets more done while using less energy. Here are some factors that can contribute to the efficiency of your designed dust collection unit.

First, reduce air leaks in the system. If there are gaps around connections, fittings, or filter bags, the suction will take more power to create. Getting the air to flow through the machine correctly and in the way you want it, is a big part of the machine design.

Additionally, be sure your moving parts are able to move freely and are maintainable and/or replaceable. Reducing the amount of time the machine is “down” can contribute tremendously to the overall efficiency of the designed system.

Make It Easy to Use

A third efficiency factor to keep in mind when considering how to design a dust collection system is its ease of use. The air flow and maintainability mean nothing if the system is not easy to use. For this reason, it is imperative that the machine not be complicated. Having the system clearly marked is one way of making sure that it is easy to use.

Another method of being sure the dust collection system is easy to use is having documentation available for the fabricators. Clearly written guides and understandable diagrams add clarity to the design. The idea is to make the system as easy to learn as possible so that newcomers do not slow down the operation of the unit when maintenance tasks or operational tasks are performed.

So there you have it. 3 main concepts to keep in mind when designing a dust collection system for your stone fabrication shop. Of course, we have already done the leg and design work for you. After all, your time is money, so every hour you spend researching and building a dust collection system, you could be making a profit. Besides, filtration systems are what we specialize in, so why not let us handle your air and water filtration systems for you.