The Benefits of Slurry Filtration

Chances are you have heard of the process. It is known by a variety of phrases. Whether you call it stone water treatment, granite water recycling, or concrete slurry filtration, the idea is the same. We are talking about the process of circulating water through a closed system while extracting, filtering, or otherwise removing the suspended particles of the “stone” material the water contains. So don’t be sidetracked by terminology as you read this post. It may not exactly match phrases you have heard. The Benefits of Slurry Filtration is the title of this article. However, The Benefits of Granite Water Recycling, Benefiting From Filtering Stone Water, or something similar could easily have been the title. The key is to recognize benefits to using water filtration systems. Professionals process concrete, stone, and ceramics using these methods regularly.

Water filtration yields various benefits when working with ceramics, stone, and concrete. But in this post, we are going to focus on three main benefits. The benefits professionals working in these industries gain are important. Health, environment, and business productivity benefit from slurry filtration. So let’s consider each of these three benefits one at a time.

Health Benefits of Recycling Slurry

The first benefit that we want to discuss when it comes to slurry filtration is its positive effects on the bodies of the workers. How so? The materials that we mentioned at the outset each contain a potentially harmful form of a very common substance; silica. More precisely, respirable crystalline silica. Is this substance really that prevalent? Well, look at the top result for the search “does concrete contain silica“, and you will find that silica is seemingly everywhere. But what is the big deal?

Some Dust Can Be Harmful

According to OSHA, not all dust is the same. As a result, silica dust is not the same as regular old dust form the ground. We won’t get into explaining the effects of respirable crystalline silica here since we have already written about it to a degree. In short, it can cause a condition called silicosis. This condition causes major health problems in the individuals that get the disease. For this reason, it is important to filter the air in environments where workers process materials mentioned above. So how does slurry filtration tie in with that?

Well, one method of preventing silica dust in granite fabrication shops is the use of wet saws and tools. These types of equipment use water to prevent dust production. However, this means that there is a high volume of water used in the shop. Also, the stone particles end up in the water and produce a liquid containing stone particles called “slurry”.

Recycling slurry is one method for managing (or controlling) the particles in the slurry. By treating the water and separating the particles from the water, you are effectively controlling the slurry. Then workers properly dispose particles of in large batches. Keeping the air clean means preventing workers form inhaling and breathing the potentially harmful dust that can cause health problems. Hence, the health benefits of slurry filtration.

Slurry Filtration is Good for the Environment

The EPA has regulations regarding the handling of slurry from concrete. In fact, as mentioned above, OSHA has standards for keeping dust containing respirable crystalline silica out of the air. In addition to those air quality regulations, the EPA enforces the Clean Water Act. These regulations and standards are increasingly raising the level of importance placed on managing slurry. How does slurry filtration improve the environment?

Air Quality

Processing materials containing silica means filtering air and keeping it as clear as possible. This is often done by using wet dust collectors or dry dust collectors. These machines remove the dust from the air to keep the environment free from dust particles that may contain harmful material. In the case of concrete slurry, it too can produce air usability issues if not disposed of properly. Particles become airborne decrease the quality of the environmental air when simply allowed to dry. However, what happens to the slurry that is produced in stone fabrication shops, concrete processing facilities, and other industries that produce potentially harmful respirable dust?

As we alluded to a moment ago, the EPA has standards that prevent certain kinds of material from just being disposed of anywhere. It certainly is not advisable to just wash slurry down the drain and forget about it. So what is the solution?

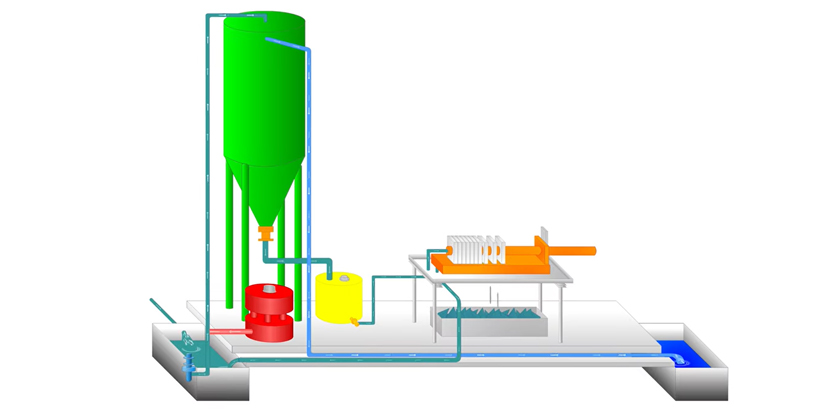

Slurry Filtration Systems

Industry professionals manage the disposal of any potentially harmful substances contained in the slurry. Thereby preventing potentially harmful substances from getting into environmental water supplies. Filtering the particles from slurry and controlling the disposal of them is a practice that ultimately contributes to a safer environment; not only for workers, but also entire ecosystems.

We have looked at the individual health benefits and environmental benefits of slurry filtration of stone, concrete, and ceramic materials. however, there is another area that benefits from the filtration of slurry; businesses.

Filtering Slurry Can Benefit Businesses

The final kind of benefit that we will discuss in this post is the benefits that slurry filtration has on businesses. For this aspect of the discussion, we will consider the specific case of stone fabrication shops. However, in principle it applies to other types of facilities as well.

Efficiency Benefits Business

Filtering slurry that is produced by say, a granite fabrication shop can impact business production. By systematically removing the particles of stone from the water, a granite shop can focus more time and energy on the actual work at hand. So there is less time spent handling the waste water since it is continually recycled and reused.

Reduction In Fines

In addition to the benefit of productivity, slurry filtration can play a vital role in OSHA compliance regarding respirable crystalline silica. By properly disposing of the stone particles removed from the slurry, stone fabrication facilities save money that could result from fines for non-compliance. Saving money in this way contributes to the bottom line of the business.

Savings On Water Costs

Finally, slurry filtration benefits businesses by reducing the amount of water the facility consumes during normal operation. By recycling water and sending it back into the system, stone shops can dramatically reduce the amount of water consumed.

All of the benefits just mentioned tremendously impact the profitability of a stone fabrication shop. Namely, the productivity boost, fewer fines, and lower water consumption.

As we have seen, there are various benefits to slurry filtration. The specific benefits of slurry filtration vary from one industry to another. However, it is easy to see that it is worth looking into. If you would like to know more about the filtration systems available from Filter Project, you can contact us and we would be glad to speak to you about your needs. Or, if you already know what you need and would simply like to get pricing, you can get a quote.