Managing Scope Creep – Keeping Projects On Track

No matter what profession you have selected, maintaining a proper view of the project (and yourself) is key. Getting either of these out of focus, can lead to a chain reaction that causes your projects to grow out of control. The creeping of features and/or the project’s scope can take over your schedule and potentially your life if not managed properly. Managing scope creep is important.

What practices can fabricators adopt to minimize “scope creep” and to keep a handle on precious time for life outside of work? Find out some practical tips to help you keep your projects on track and manageable. In this article, we will take a look at how to keep your projects from growing uncontrollably. You might be surprised at what trips some people up.

Setting Sights Too High

Managing scope creep means having the proper view of goals. High goals is one of the first things that can set you on a path of over-demanding work. Working on fabrication projects that end up demanding more of your time and energy is related to the amount of ambition you have for growing your business.

Don’t take that the wrong way, it does not mean that you have to put all your ambition aside. There is nothing wrong with wanting to grow your business in and of itself. However, the thing to keep in mind is this:

The greater hopes for growth that you have, the more you must be willing to invest in your business. Whether it is time or energy, an investment must be made if your fabrication business is going to grow. If you are not up to the challenge of putting in the extra time it takes to expand, you must be willing to get additional help. Otherwise, you could be setting yourself up for a heavy workload.

Taking On Too Large of Workload

If you do have ambitions to grow your business but you are not ready to invest in hiring additional manpower, this is the obstacle that you could find yourself facing. Why is that the case?

Well, if you are wanting to grow the business but you also want to keep your time constraints, you will need to decide ahead of time what your workload limit is. Once you have taken on enough work that you have reached your maximum workload potential there will be 3 factors that you will need to weigh:

- Assistance

- Efficiency

- Higher Prices

These three factors will affect your business’s profitability, so once you have reached your maximum allowable workload, you will need to use one of these three solutions in order to continue expanding, or make more money without expanding.

If you fail to adjust, the risk of scope creep grows. As clients begin asking for additional services, or your desire to provide exceptional customer service causes you to go above and beyond, you will find yourself at odds with the workloads maximum that you have established for yourself.

However, by applying the first two factors in the list above, you can resist scope creep and keep your business growing at a manageable rate.

Lack of Effective Tools

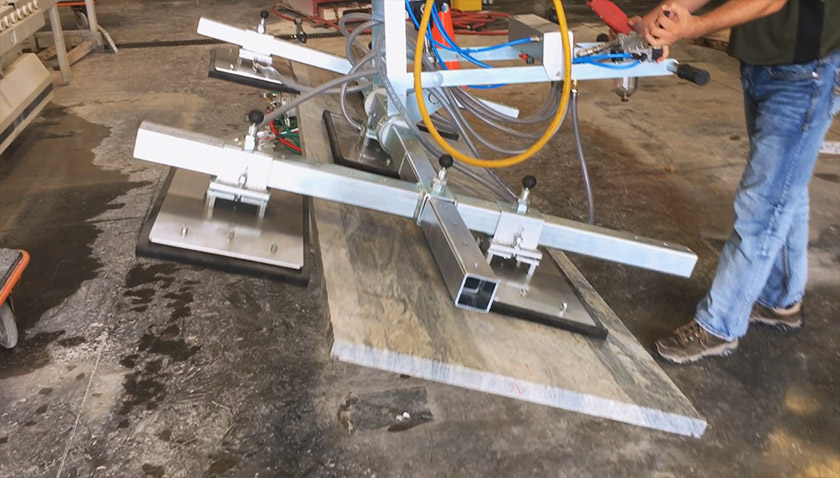

The third tactic that you can make use of to effectively stave off your workload creeping out of control is to increase your efficiency. This helps tremendously in managing scope creep. There is more than one way to boost your shop’s efficiency. But the way that we are going to focus on here is making use of better fabrication tools and other tools as well.

By making use of better tools to increase efficiency you in effect, free up time. Then you have the ability to use that time to do more of the profitable services that you once had no time for.

It goes without saying that the less expensive the tools are and the more efficient they are, the more time you will be able to recover.

Also, do not limit your ability to streamline by means of effective tooling be limited to fabrication equipment. There maybe fabrication management software that allows you to get more accomplished in a smaller amount of time. It could be a piece of software that assists you in scheduling, managing projects, or communicating with fabrication teams. The idea is this; free up time so you can fit more of your workload into that free time.

In conclusion, you can see that keeping your business expansion manageable is possible by taking care of some basic aspects of efficiency. If your goals are high, you will probably find yourself putting one or more of these tactics to use multiple times during the growth of your fabrication shop. The idea is to have a plan of how you plan on accomplishing your business’ growth and sticking to that plan.