Industrial Filtration Units

Industrial shops like stone fabrication shops benefit from a wide variety of industrial equipment. Air tools and power tools like bridge saws, polishers, and vehicles like fork lifts and booms are only part of the story though. There are other types of machines that could be classified as industrial filtration units as well. In this post, we will consider some specific types of filtration units that industrial shops like stone fabrication plants use while producing countertops, work surfaces, and even floor tiles and wall panels.

Industrial Dust Collection System

The first type of industrial filtration units we will examine are industrial dust collection systems. These units perform a vital function in the stone fabrication environment. They remove fine dust particles from the air by using one of two methods; water or air. We will briefly consider each of these dust management methods here. Afterward, we will look at another type of filtration unit that you will commonly find in the stone fabrication industry.

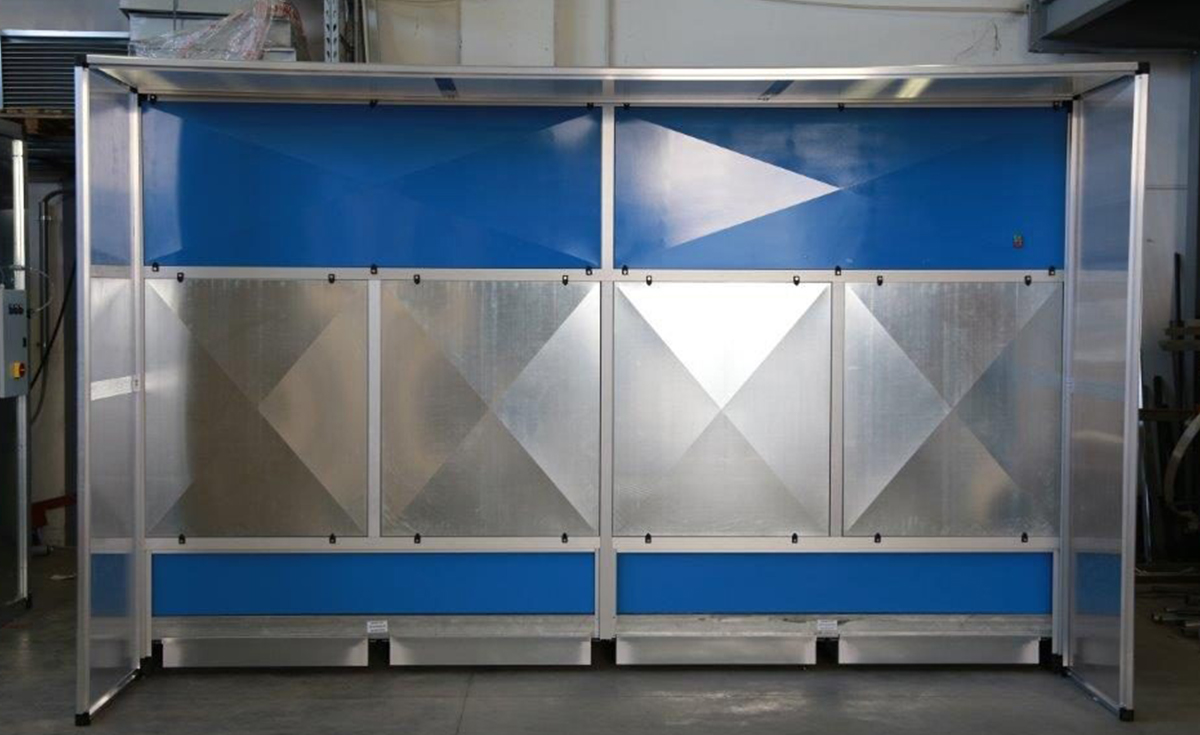

Dry Industrial Dust Collectors

Using air currents, dry industrial dust collectors move the particles into a cabin-like unit in which is an array of filters. Air passes through the filters. The particles are left behind. Then, the air is circulated back out to the work area. As a result, it becomes part of the next current that brings the flow of stone dust into the filtration unit for removal.

As the air flows in and out of the dry dust filtration unit, this cycle repeats. Periodically, filter bags need to be changed, dust needs to be emptied from drawers in the bottom of the unit. However, overall these dry units filter the stone dust produced in a fabrication shop well.

Wet Industrial Dust Collection Units

Another method used for filtering stone dust from a fabrication work area is wet industrial dust collection units. These units filter dust from the work area in a fashion similar to the dry units mentioned above.

First, the industrial filtration unit creates an air current. Then the current draws the dust from the granite, marble, quartz, or other stone material into the collection unit. Up to this point, everything sounds the same. However, once the air current enters the wet dust filtration unit, it meets with a flow of water running down a vertical wall. Hence, wet industrial dust collection systems are called “water walls”.

The water stream captures the dust and it lands in the sludge reservoir; or settling tank at the bottom of the unit. The stone particles settle to the bottom of the tank. The water then is pumped back up to the top of the filtration unit. Then, the water is ready for another pass down the wall to pick up the wave of particles entering the wet filtration industrial unit.

So, when it comes to industrial filtration systems, Filter Project USA offers both wet filtration and dry filtration for stone dust. However, filtration units for industrial fabrication shops do not end with dust filters. As many are aware, there is an entire realm of fabrication production that operates in a wet environment. We’ll take a look at filtration units for water next.

Industrial Water Treatment Solutions

Even though stone fabricators do a great deal of work in a dry environment, there is also a wet environment in which fabrication pros work. This environment is where industrial water treatment solutions come in. Wet cutting, wet coring, and wet polishing use a constant, steady flow of water. Like the wet dust collection system mentioned above, these wet tools utilize water to carry the stone “slurry” away; preventing the dust form ever entering the air. Yet, the particles of stone must go somewhere.

These industrial units are basically systems that carry the water through a filtration process of one type or another. Let’s take a look at some industrial water recycling systems that you can find being used in fabrication shops.

Industrial Lamellar Units

These industrial water filtration units are designed to recycle water and send it back into the shop where it can be reused for the following tasks, among others:

- Wet Cutting

- Using Wet Polishing Pads

- Wet Coring Tools

Filter Project USA lemellar units are installed outdoor or indoor. Hence, these are available in a range of capacities depending on the size of industrial shop.

Filter Press Units

Stone fabrication professionals enhance the rate at which water is recycled through the filtration system. In fact, fabricators accomplish this by utilizing filter press units. Additionally, Filter presses are available in a variety of sizes and are produced by Filter Project in both automatic and manually types.

Industrial Stone Water Treatment Units

Filter press technologies effectively reduce water costs associated with the stone fabrication industry. Furthermore, these machines range from 211 GPM units to 925 GPM treatment units. So consider looking into “silo style” industrial water treatment units. Especially if you are thinking of adding on to your shop. You can find them at:

- CH 25 Industrial Silo Unit

- CH35 Industrial Filtration Unit

- CH45 Silo Filtration Unit

- CH55 Industrial Silo Filtration

- CH80 Industrial Silo Filtration Unit

As you can see, there are plenty of uses for industrial filtration units in the stone fabrication industry. In fact, a wide range of equipment exists for filtering stone dust. Water and air filtration produces multiple possibilities for stone fabrication professionals. Pros use these systems to increase efficiency and streamline the workflow.