Water Treatment Technologies

When discussing stone wastewater treatment, the topic of technology is bound to come up. In fact, the concept of recycling water in granite shops and in marble fabrication facilities is chock full of water treatment techniques that contribute to the recycling process. Taking a closer look at the water treatment technologies is eye-opening. In this post, we will consider a few of the many techniques for treating water that have come to be staple technologies in the stone fabrication industry.

Why Water Treatment Techniques Are Important

We cannot explore the technologies without first understanding why they are important to stone fabrication professionals. Why are water treatment technologies so important to the granite and marble industry? Well, recycling waste water has a number of benefits for stone fabricators. We won’t go into all the details here, but if you would like to get an idea of how water is involved in stone fabrication shops, you can check out this stone fabrication water recycling benefits article to learn more. But, to summarize it, waste water treatment technologies make a granite shop more efficient and profitable.

Water Treatment Overview

Granite shops use water for a number of processes. In fact, there are many other industries that reuse water in a variety of ways. Yet, running filtered water back through a fabrication shop to use it a second time requires more than one technology to accomplish the task. Let’s consider some of the techniques that can contribute to those benefits.

Sedimentation Process

Sedimentation is a water treatment process that plays a big part in recycling water. This technique uses gravity (and other forces) to separate particles from water. You may not readily think of sedimentation as a technology or a technique. However, in reality sedimentation technology plays a significant role in water treatment. Thus, sedimentation is a technology that is found in the water filtration cycle.

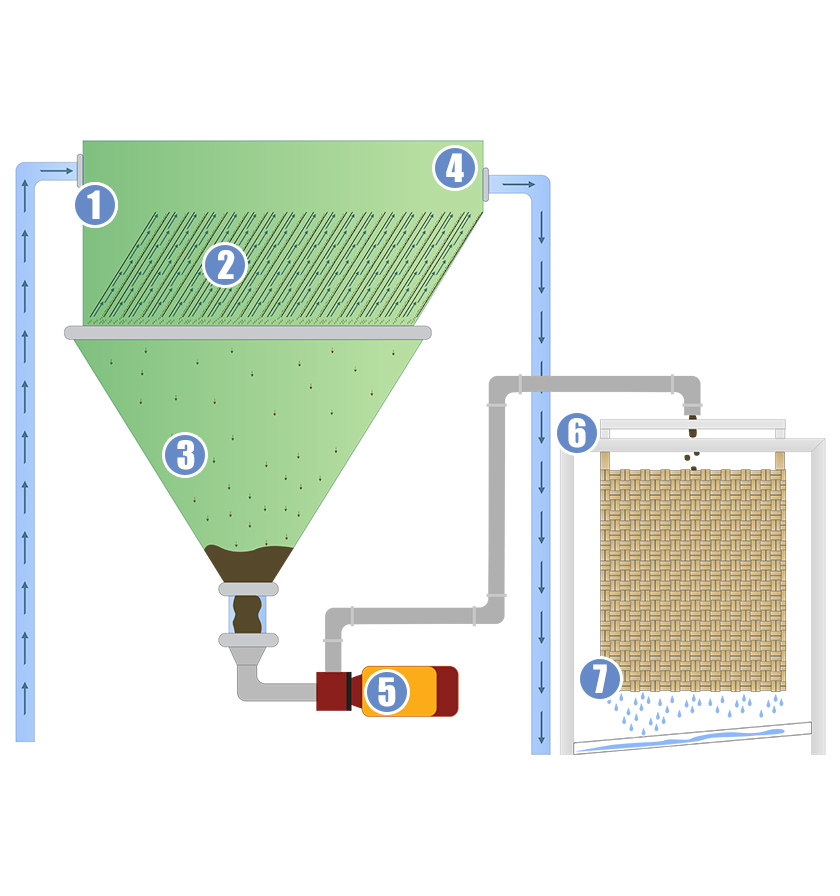

Lamella Clarification

Lamella clarifiers are a specific kind of settling tank that use an array of inclined plates. These plates collectively form a large amount of surface area which plays an important role in the sedimentation process. The plates allow for the settling of particles in a smaller area since they facilitate the movement of the particles downward more quickly. If you would like to get a better idea of how this process works, you can check out our interactive diagram of the lamellar clarification components. The Lamellar technique is another water treatment technology that impacts water filtration.

Dehydration In the Water Treatment Process

You may be wondering, “How in the world does dehydration figure into the water treatment process?” On the surface it sounds counter-intuitive, yet in reality dehydration plays a large role in water treatment. Why is that the case?

In order to treat water for reuse – whether it is for potable water or as grey water – any solids that are suspended in the water must be removed. Dehydrators remove any remaining water from the “sludge”. Dehydration technology is important to the water treatment process. In fact, it is anohter way that water is removed from the solids suspended in the pre-treated water. There are a variety of methods for dehydrating remaining water form solids; some of these include:

- Filter Presses

- Thermal Drying

- Filters

- Band Filters

- Vacuum Filters

- Centrifugal Force

Although there are a number of methods through which dehydration can be accomplished, they allow for the solids to be transported easier since they are lighter. On the other hand, the water that is removed is either reused, or further clarified.

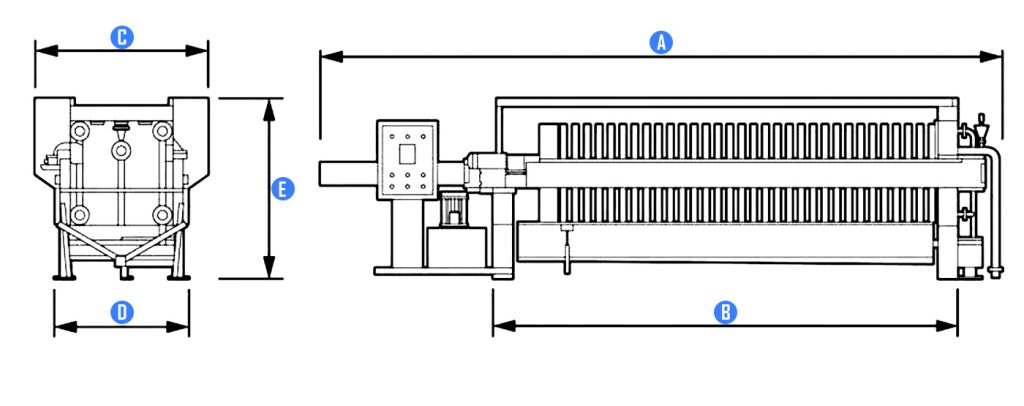

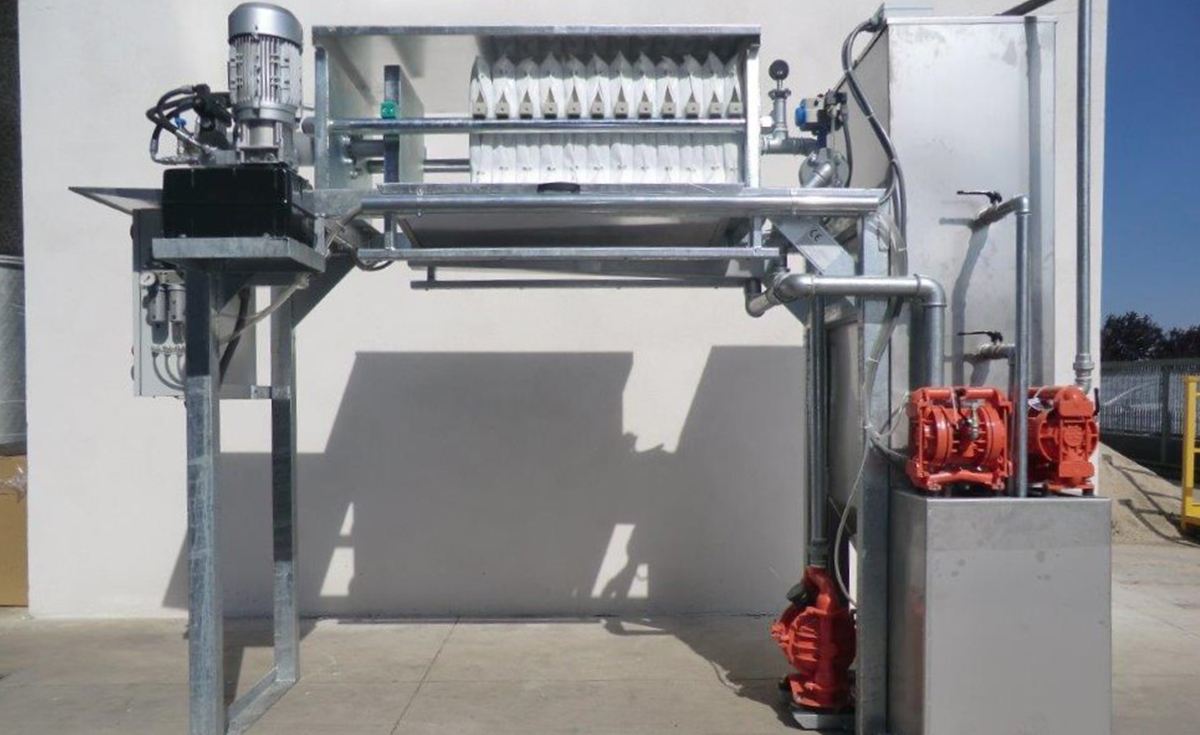

Filter Presses In Water Treatment

One of the ways dehydration is accomplished is by using filter press technology. A filter press does just want the name implies, it filters out solids from the water by “pressing”. When the press runs, it squeezes the water out of the sludge to produce a “cake”. If you would like more detail on how a filter press works, there is a page on this site that talks about granite fabrication filter presses.

Why Water Needs to Be Treated

This is an idea that is central to the stone fabrication industry. In stone fabrication shops many of the processes use water for a couple of purposes. These purposes are:

- Keep the stone cool during polishing, grinding, or cutting.

- Removing dust from the work environment.

Both of these purposes contribute to safety. For example, keeping a blade cool during cutting is an important part of safety. If a blade overheats, it can throw segments or even break. Yet, stone dust can be a hazard as well.

The other purpose of water in the stone fabrication shop is to remove dust from the air. Not only can dust cause temporary breathing challenges, it can also be factor in the long-term safety of stone fabrication professionals. For clarification of that statement, you can check out how dust and safety are involved in the stone industry.

Wet Dust Extractors

Dust extraction technology also uses water. Fabrication professionals remove dust from the air with dust extraction equipment. These come in both dry and wet machines. The wet dust extractors (A.K.A. water walls) pull the dust into a stream of running water as it flows down a flat surface. After that, water is separated from the particles must so the water is fit for reuse.

As we have seen, there are many technologies that play a role in the water treatment process. From the separation methods to the actual use of the water in the granite fabrication process, water treatment technologies are an integral part of, not only how your stone surfaces get produced, but also the safety of the professionals involved.

One thought on “Water Treatment Techniques”

Comments are closed.