Lamellar Water Clarifiers

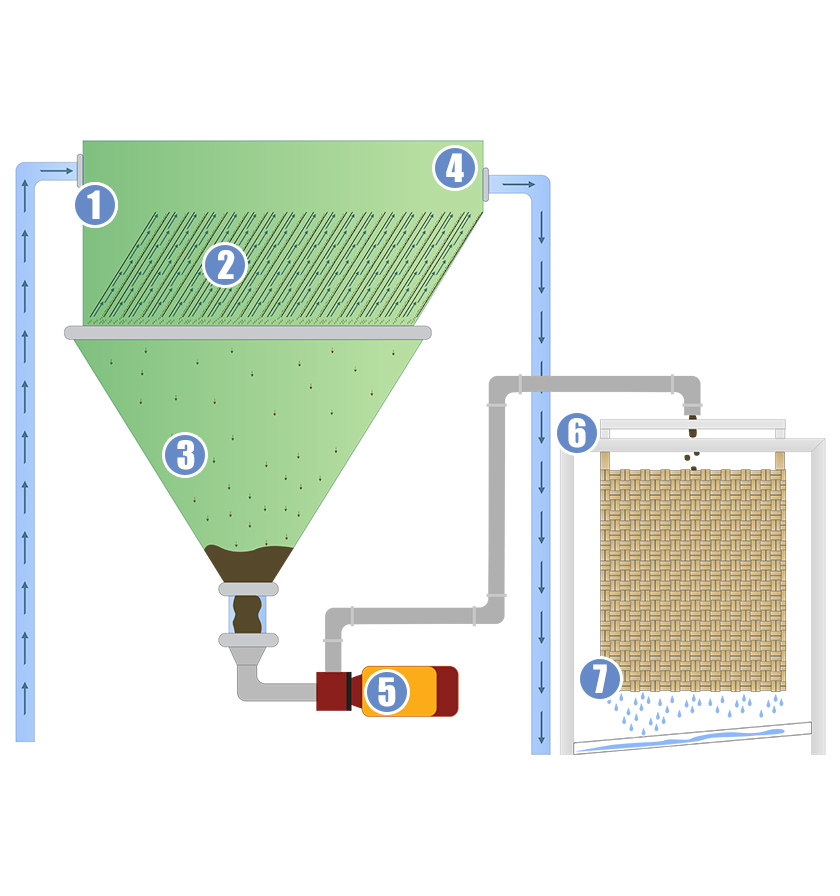

The Filter Project lamellar water clarification plants utilize a multi-step process that removes particles from stone waste water produced by granite fabrication shops. Hence, to see more information regarding the lamellar separation process, hover over the number on the image below. You can read about some of the aspects of the process by clicking the number that represents the task in the image.

The inlet channel for “influent” facilitates the entering of water and particles into the clarification unit. Additionally, this water may or may not already have been put through the the coagulation and flocculation processes.

These packs are plates that sit at a precise angle and allow water to flow through them in an upward motion. They also assist the particles in making their way to the bottom of the water clarifier.

Particles fill the hopper as they settle by means of gravity. Hence, they collect at the bottom and an extraction process removes them from the hopper. For example, this diagram shows an extraction pump at location number 5.

The “effluent” (clarified water) exits the clarification system through the outlet channel. Afterward, the water clarification system sends the processed water to a container for reuse in the shop or passed along as waste water.

The mud extraction pump removes collected sludge from the clarification system. However, the sludge still contains water, so some additional filtering needs to takes place.

Filter bags (shown in location 7) hold extracted sludge. Hence, this part of the system suspends the bags for this part of the clarification.

Gravity extracts additional water from the sludge (or mud) pulled out of the system. Filter bags hang above a catch basin. As a result, gravity draws additional water out of the mud, thus leaving the extracted particles.