AS 400 Automatic Filterpress

The AS 400 is a machine that dehydrates sludge. The filterpress is a widely used method of separating sludge into its two primary components; the solid and water. Pressure is generated inside the filtering chambers by means of special pumps.

The AS 400 Filterpress is made to your needs using electro-welded steel that is then specially painted. Or, if you prefer, you can choose to have it hot galvanized. Each part of the filterpress that is exposed to liquid is made using aluminum alloy or stainless steel so you do not have to worry about rust. The plates of the filterpress are available in either fixed or variable volume. Hence, you are able to respond to a variety of challenges with the AS 400. The filterpresses in the AS series are available in a host of specifications and depending on which machine you choose, you can equip it with the following:

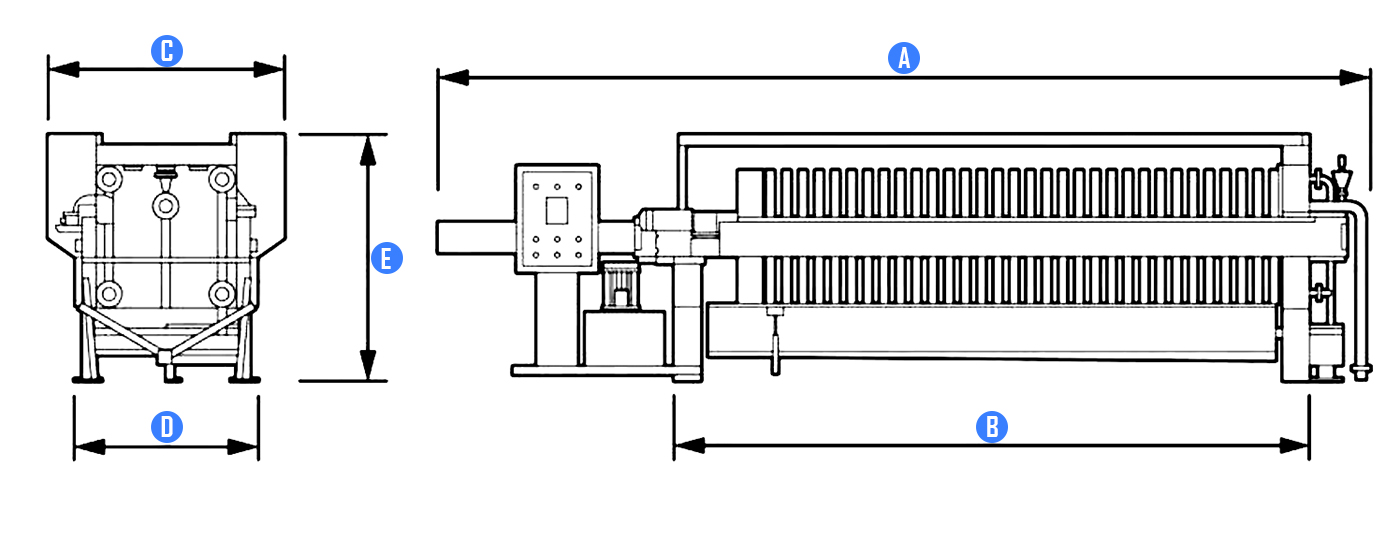

| AS 400 Filterpress Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Plates Dim. | Plates | Total Volume | Total Power | Weight | Dimension | |||||

| C30 | C45 | A | B | C | D | E | |||||

| AS 400 | 400×400 | 4 | 9 | 13 | 1.1 Kw | 800 | 2,350 | 2,100 | 850 | 750 | 1,860 |

| 8 | 21 | 31 | 900 | 2,500 | 2,100 | ||||||

|

|||||||||||

AS Series Optional Features

- Gangways Alog the Machine’s Perimeter

- Supporting Structure

- External Cover for Protection

- Automatic Filter Washing

- Other Automations

Full Line of Filterpress Equipment

Filter Project offers a variety of automatic filterpresses. The AS 400 is one of the filterpresses we use for our water recycling equipment. Each of our wastewater clarification and recycling machines makes use of one of these filterpresses. The following table shows the specifications for our filterpresses.

| Filterpress Technical Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Plates Dim. | Plates | Total Volume | Total Power | Weight | Dimension | |||||

| C30 | C45 | A | B | C | D | E | |||||

| AS 300 | 300×300 | 4 | 6 | 9 | 1.1 Kw | 700 | 2,350 | 2,100 | 700 | 600 | 1,760 |

| 8 | 14 | 21 | 800 | 2,500 | 2,100 | ||||||

| AS 400 | 400×400 | 4 | 9 | 13 | 1.1 Kw | 800 | 2,350 | 2,100 | 850 | 750 | 1,860 |

| 8 | 21 | 31 | 900 | 2,500 | 2,100 | ||||||

| AS 500 | 500×500 | 5 | 20 | 30 | 2.45 Kw | 1,100 | 2,050 | 1,345 | 1,010 | 1,010 | 1,600 |

| 8 | 36 | 53 | 1,250 | 2,500 | 1,805 | ||||||

| 10 | 46 | 68 | 1,350 | 2,850 | 2,240 | ||||||

| AS 630 | 630×630 | 5 | 35 | 53 | 2.45 Kw | 1,250 | 2,050 | 1,345 | 1,140 | 1,140 | 1,660 |

| 8 | 62 | 92 | 1,400 | 2,500 | 1,805 | ||||||

| 10 | 78 | 118 | 1,600 | 2,850 | 2,240 | ||||||

| 15 | 122 | 184 | 1,750 | 4,000 | 2,990 | ||||||

| AS 800 | 800×800 | 10 | 136 | 180 | 6.45 Kw | 3,000 | 3,625 | 1,870 | 1,450 | 1,080 | 1,985 |

| 15 | 212 | 280 | 3,400 | 4,670 | 2,620 | ||||||

| 20 | 288 | 380 | 3,800 | 5,715 | 3,370 | ||||||

| AS 1000 | 1000×1000 | 15 | 329 | 490 | 6.45 Kw | 6500 | 4,800 | 2,680 | 1,800 | 1,280 | 2,015 |

| 20 | 446 | 665 | 7,000 | 5,950 | 3,430 | ||||||

| 25 | 564 | 840 | 7,500 | 7,100 | 4,180 | ||||||

| 30 | 680 | 1,015 | 8,000 | 8,250 | 4,930 | ||||||

| AS 1200 | 1200×1200 | 31 | 960 | 1,440 | 12.45 Kw | 12,000 | 8,559 | 4,348 | 2,230 | 1,620 | 2,303 |

| 41 | 1,280 | 1,920 | 14,000 | 9,704 | 5,493 | ||||||

| 51 | 1,600 | 2,400 | 16,000 | 10,849 | 6,638 | ||||||

| 61 | 1,920 | 2,880 | 18,000 | 11,994 | 7,783 | ||||||

| AS 1500 | 1500×1500 | 31 | 1,545 | 2,310 | 12.45 Kw | 21,000 | 8,559 | 4,348 | 2,530 | 1,920 | 2,603 |

| 41 | 2,060 | 3,080 | 23,000 | 9,704 | 5,493 | ||||||

| 51 | 2,576 | 3,850 | 25,000 | 10,849 | 6,638 | ||||||

| 61 | 3,090 | 4,620 | 27,000 | 11,994 | 7,783 | ||||||

More Filterpresses